Unique system that enables speedy production

Since our establishment in 1974, we have been active in Japan and overseas as a system capable of producing high quality products at high speed. We offer design, manufacturing, installation, adjustment, trial and after-sales service as well as

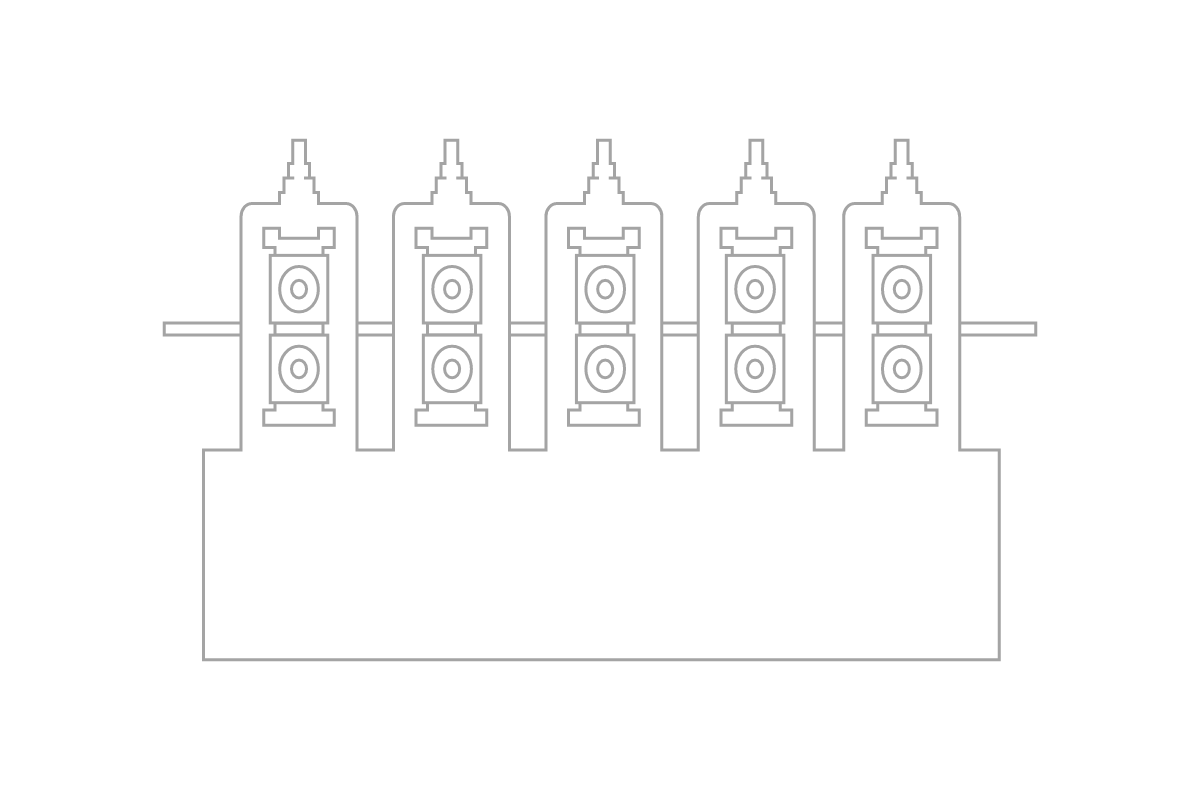

About Forming Roll

As the name implies, it means a “rotating” die. Multiple forming rolls are incorporated into a cold roll forming machine, and by passing strip steel sheets through them, various shapes can be efficiently manufactured.

Roll Forming

Each of the rotating forming rolls acts to form the steel sheets that pass through the gap into various shapes according to the purpose and specifications.

Before molding

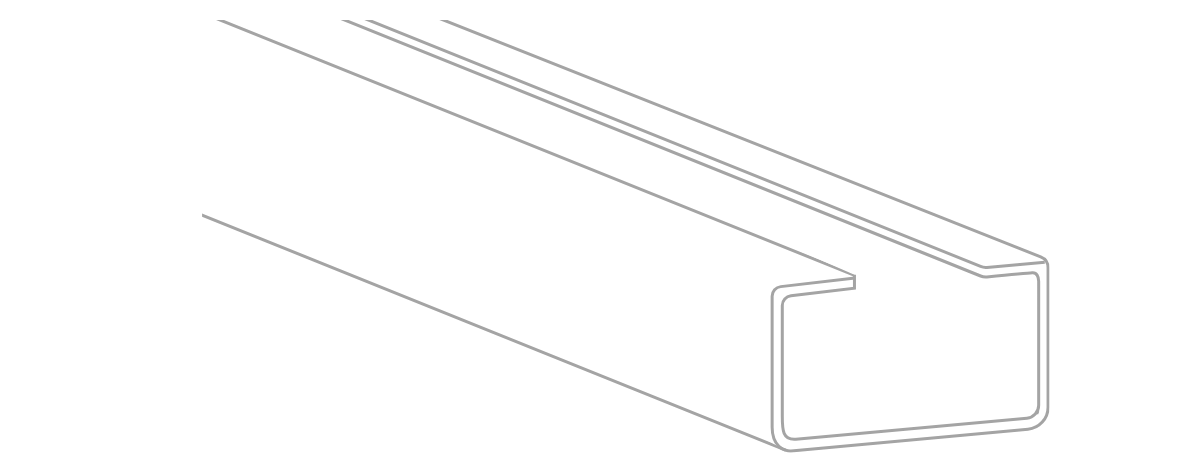

After molding

About materials

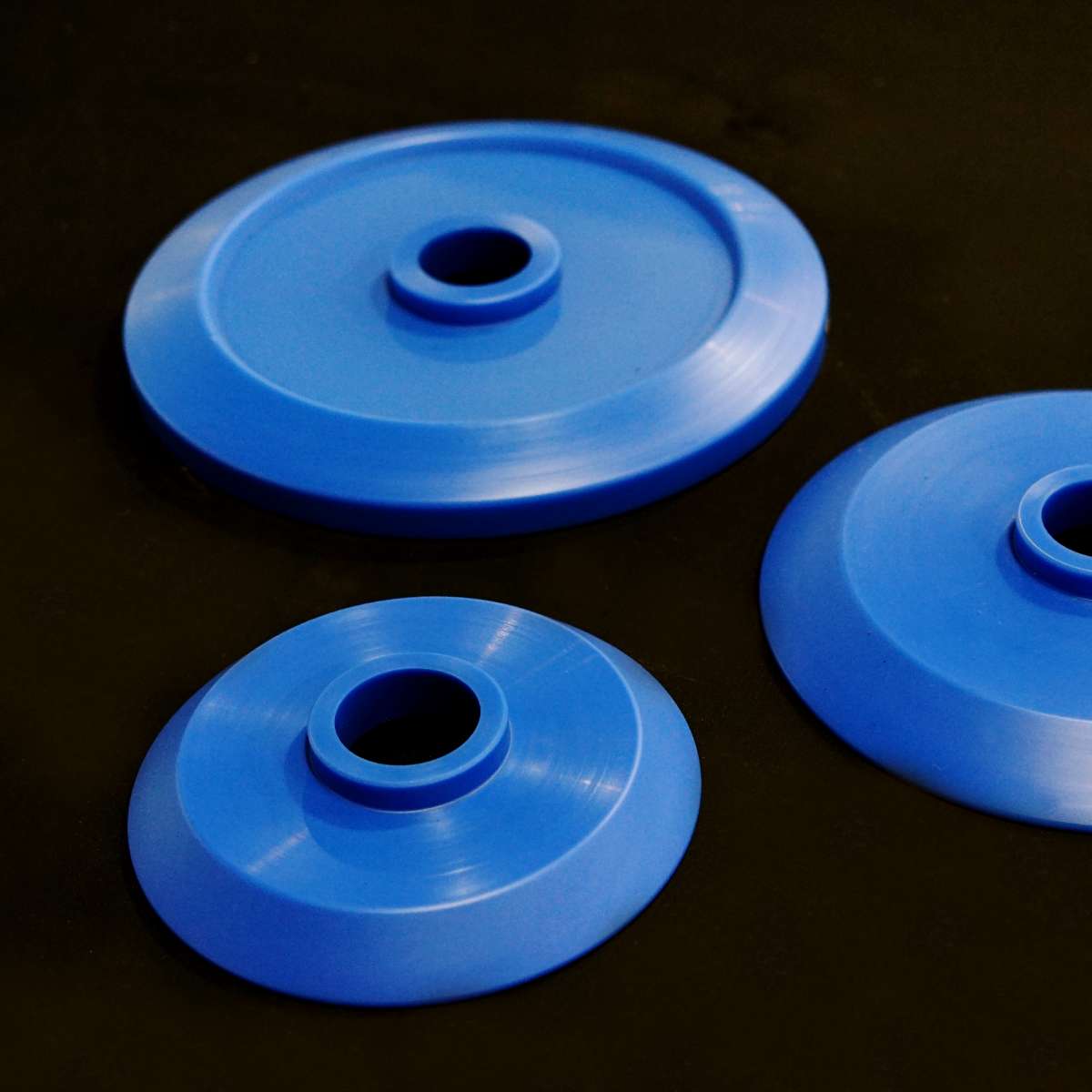

Roll forming is possible using forming rolls made of a wide range of materials depending on the situation.

Carbide roll

ceramic roll

SKD11

OM Alloy material

nylon roll

Manufacturing Process

All processes required for the production of forming rolls are carried out in an integrated manner within the company.

design

Material Cutting

machining

heat treatment

quality check

test run

supply

Business Strengths

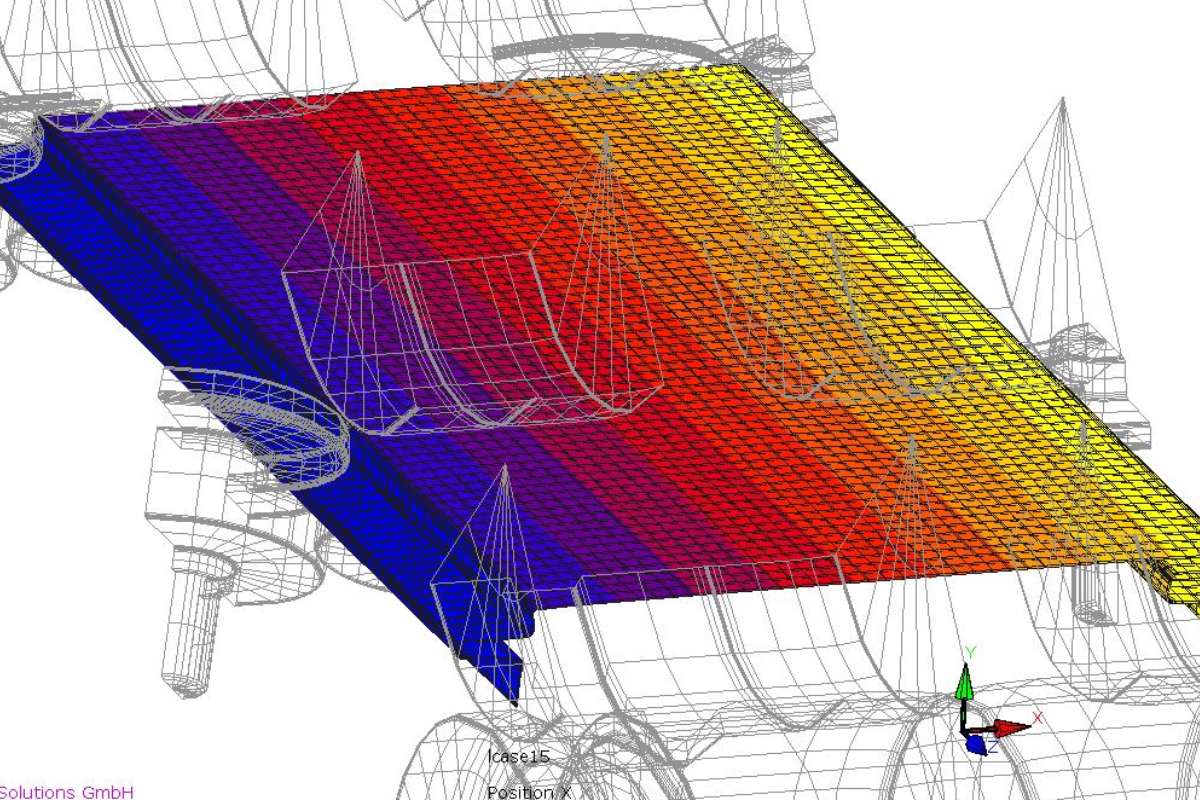

Use dedicated analysis software

Based on the designed drawings, simulations are performed using 3D analysis software dedicated to forming rolls, and products are produced according to the cross-sectional shape drawings with no errors.

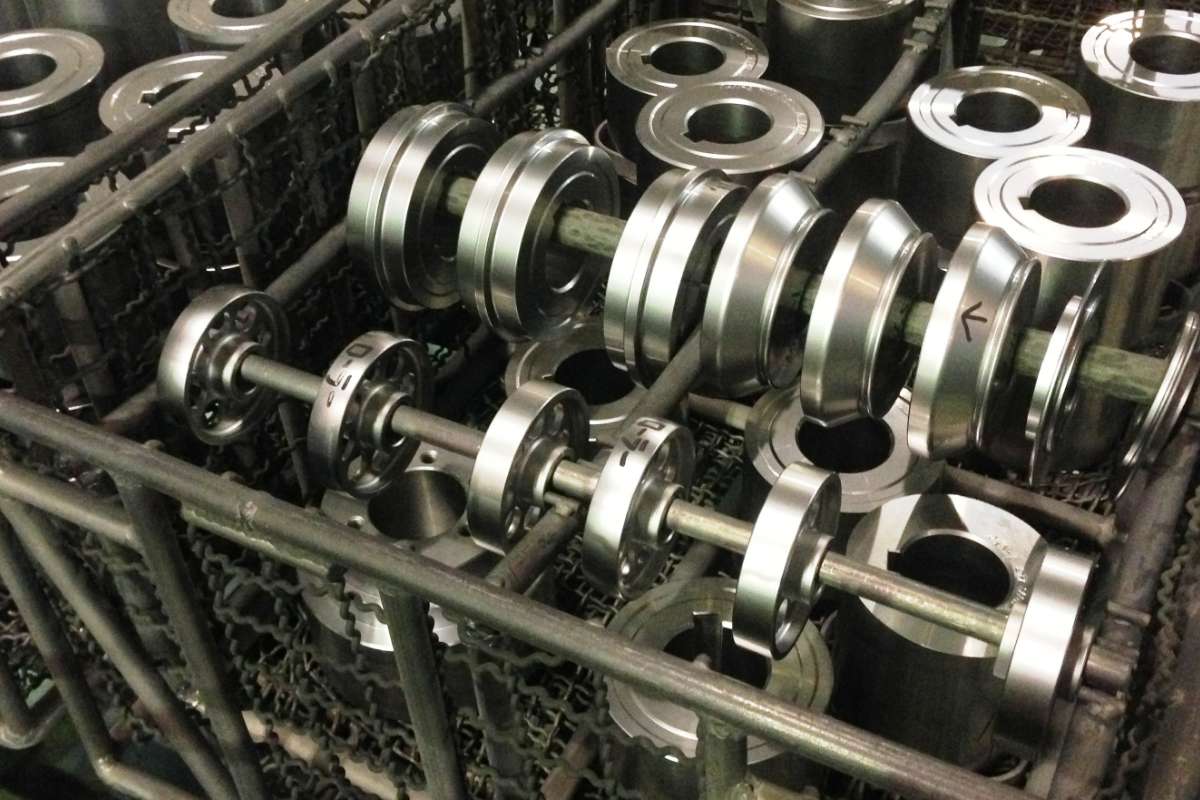

In-house storage of materials

For products 400 mm in diameter or larger, we store materials in-house so that we can begin machining immediately after receiving an order.

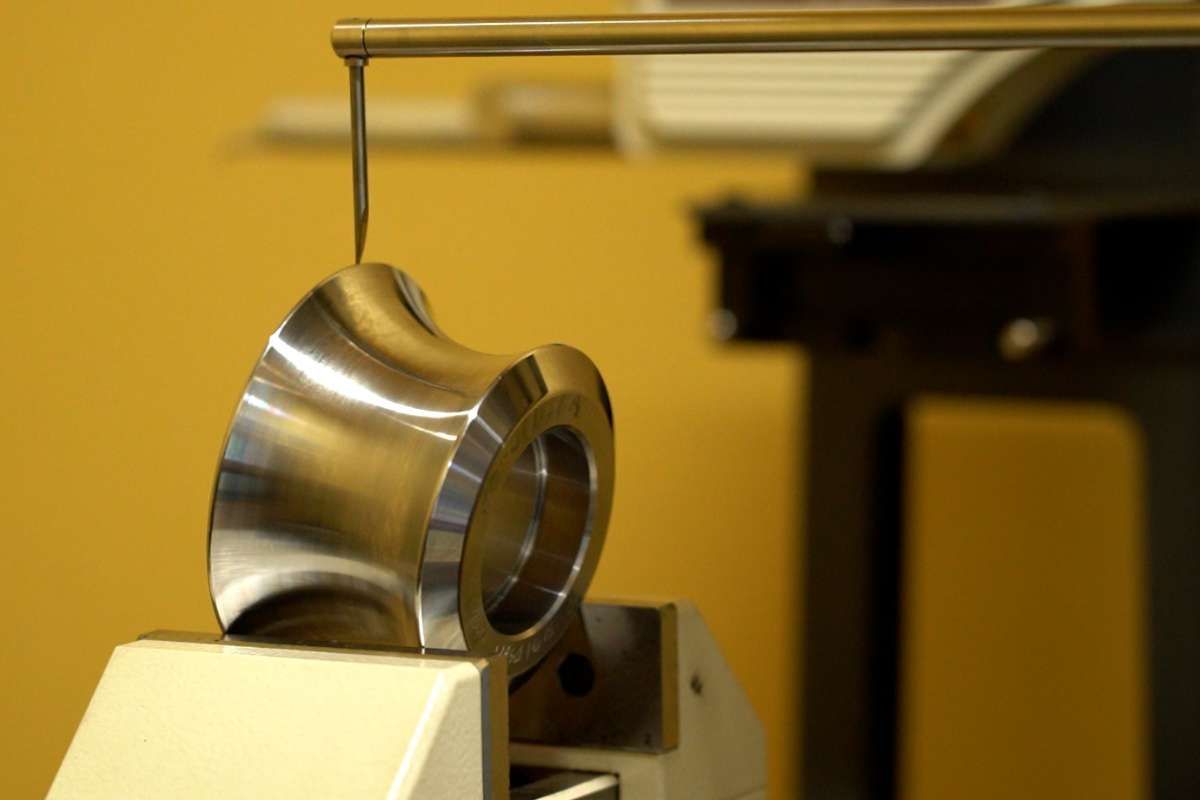

High commitment to precision

We provide ultra-precision machining with a focus on accuracy to meet customer needs using technology cultivated over many years and a wealth of machining facilities.

Advanced heat treatment technology

We have the latest heat treatment equipment in-house, and our unique system has enabled us to produce products that are resistant to cracking and abrasion.

Thorough quality control

Thorough quality control is performed using precision measuring instruments. In particular, calibers can be inspected using three-dimensional measuring instruments and contracers, etc., as needed.

In-house test run conducted

We perform test runs to ensure that products function properly using our self-developed specialized machines. We can confirm the shape of the specified product before delivering it to the customer.

To Our Corporate Customers

Catalogs containing detailed information on our technologies

and products can be viewed and downloaded below.