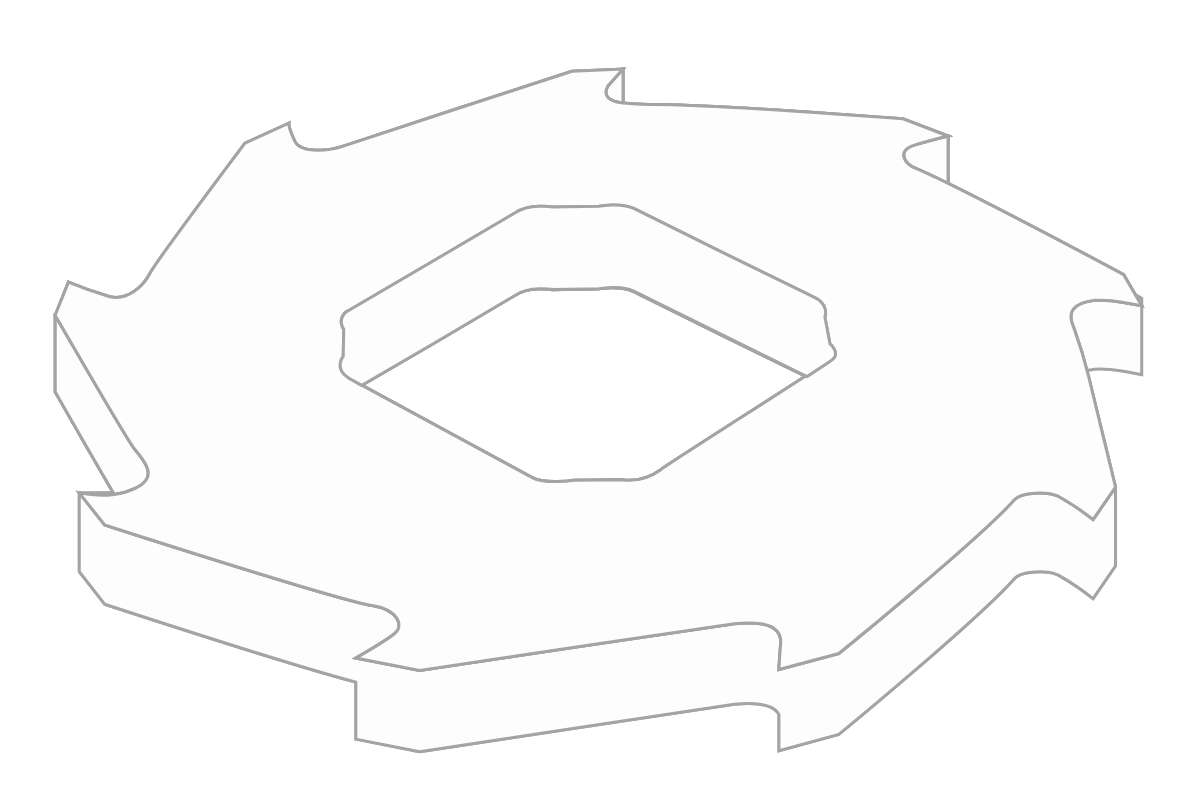

Reminiscent of a sword

sharpness and durability

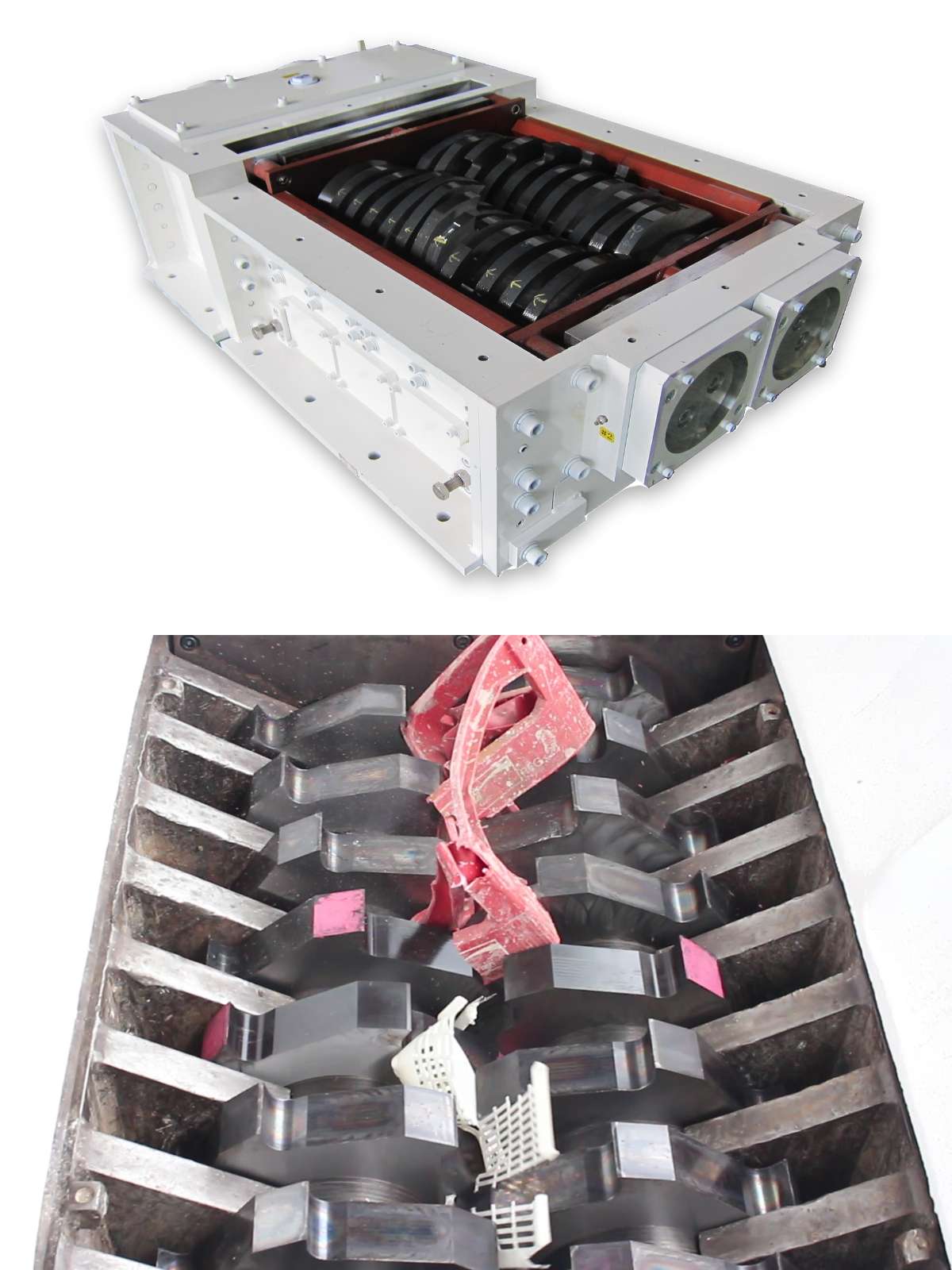

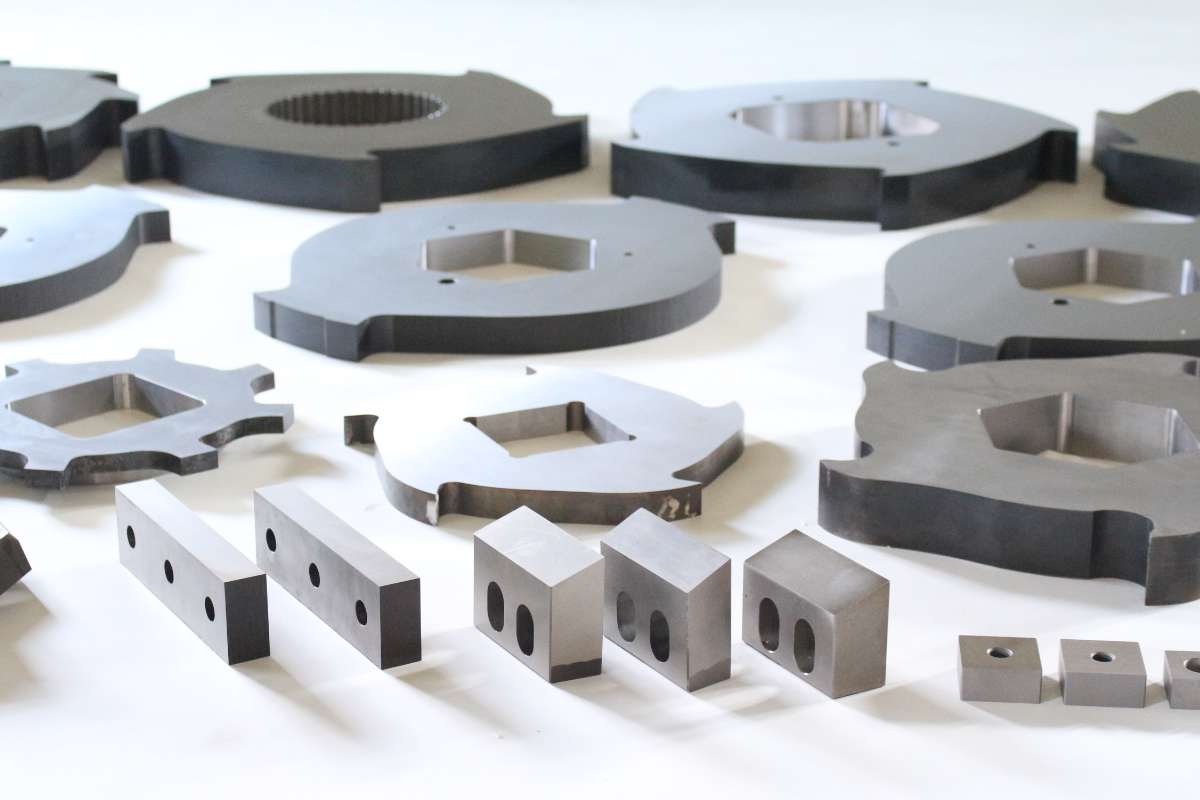

We have been engaged in heat treatment of forming rolls since the company’s foundation, and about 20 years ago, the Environmental Equipment Manufacturing Department was established to design and manufacture crushers and crusher blades, as well as to perform maintenance of crushers as a whole. The Environmental Equipment Manufacturing Department was established about 20 years ago to design and manufacture crushers and crusher blades, as well as to provide maintenance services for crushers as a whole.

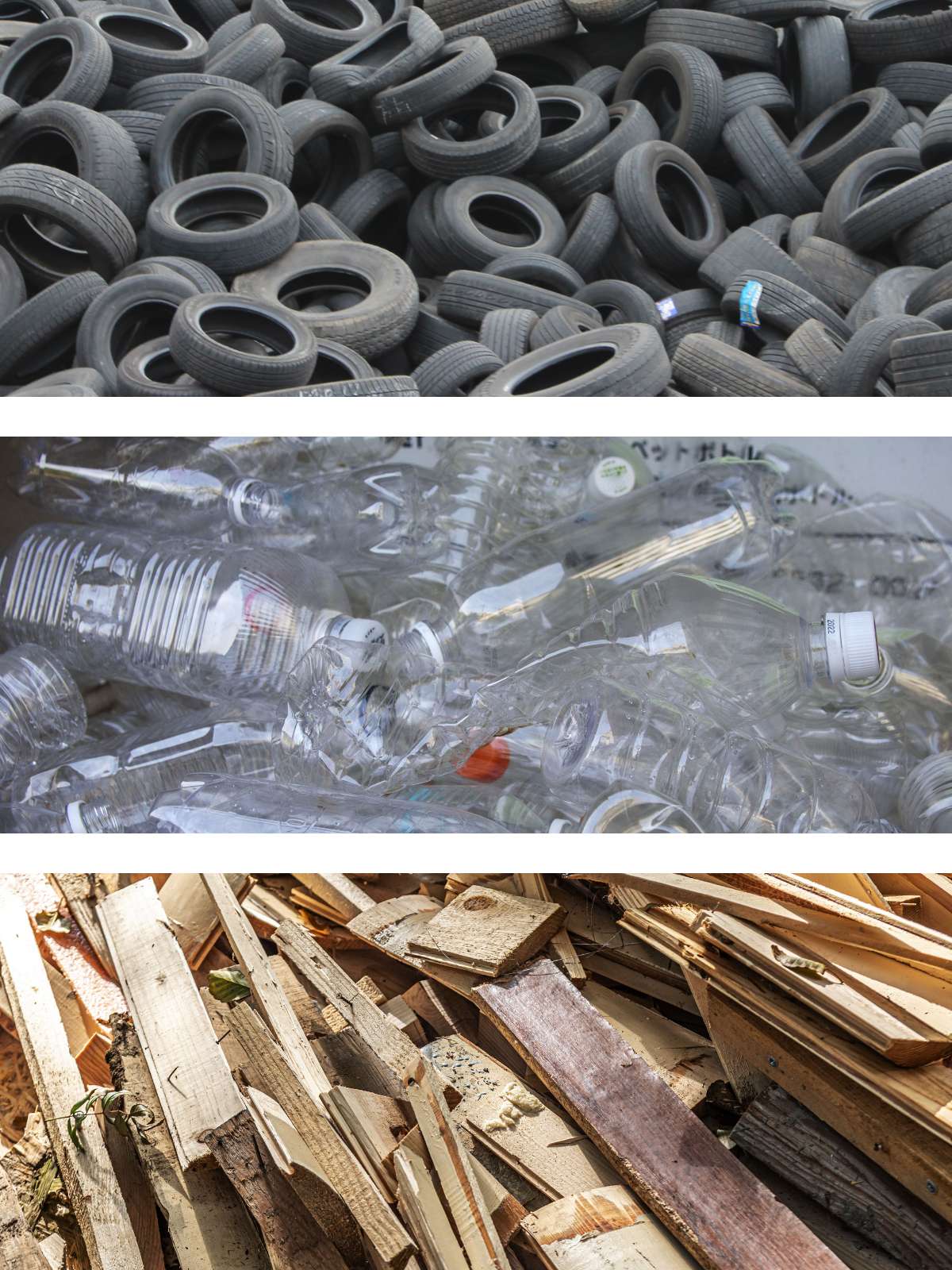

Role of the crusher

We play an important role in a recycling-oriented society by efficiently and safely processing industrial waste and other materials for recycling.

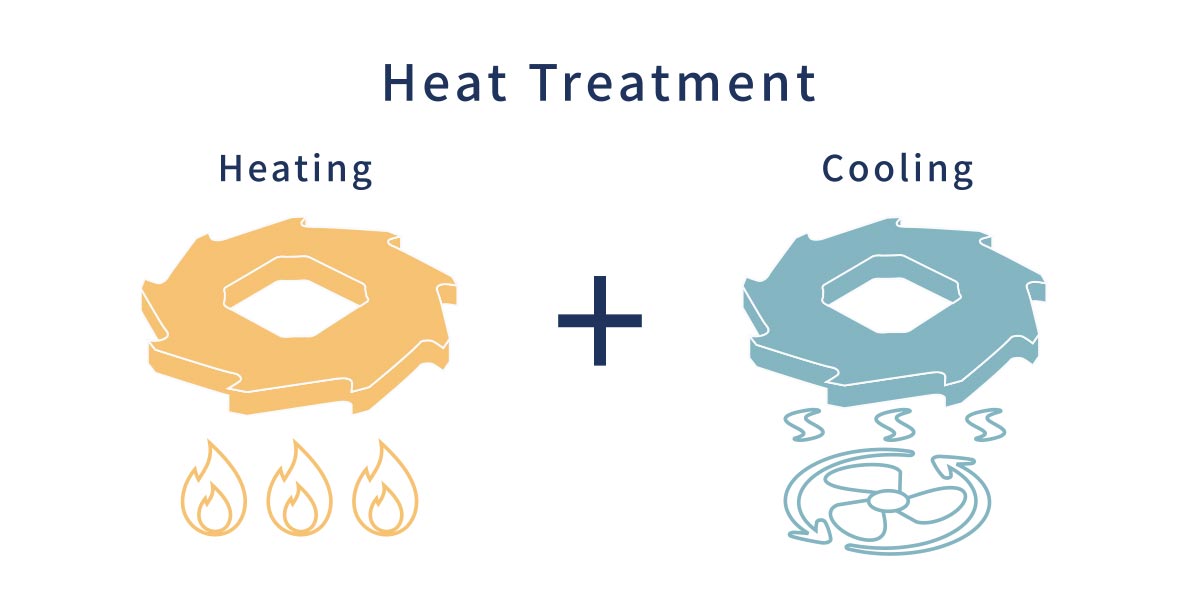

Heat Treatment

Heat treatment is the process of heating and cooling a metal to change its properties and give it hardness and toughness.

production system

production process

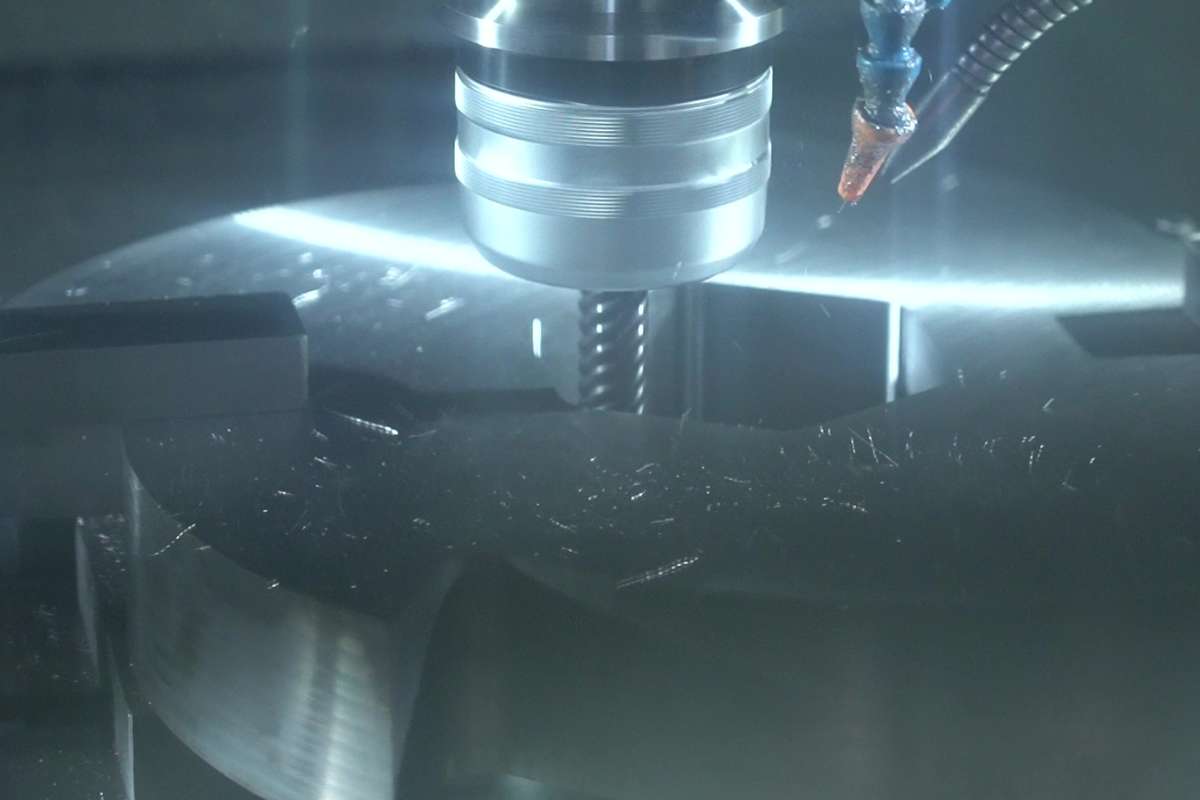

(1) Material Cutting

(2) Shape processing

(3) Metal heat treatment

(4) Hardness test

(5) Surface polishing

Other

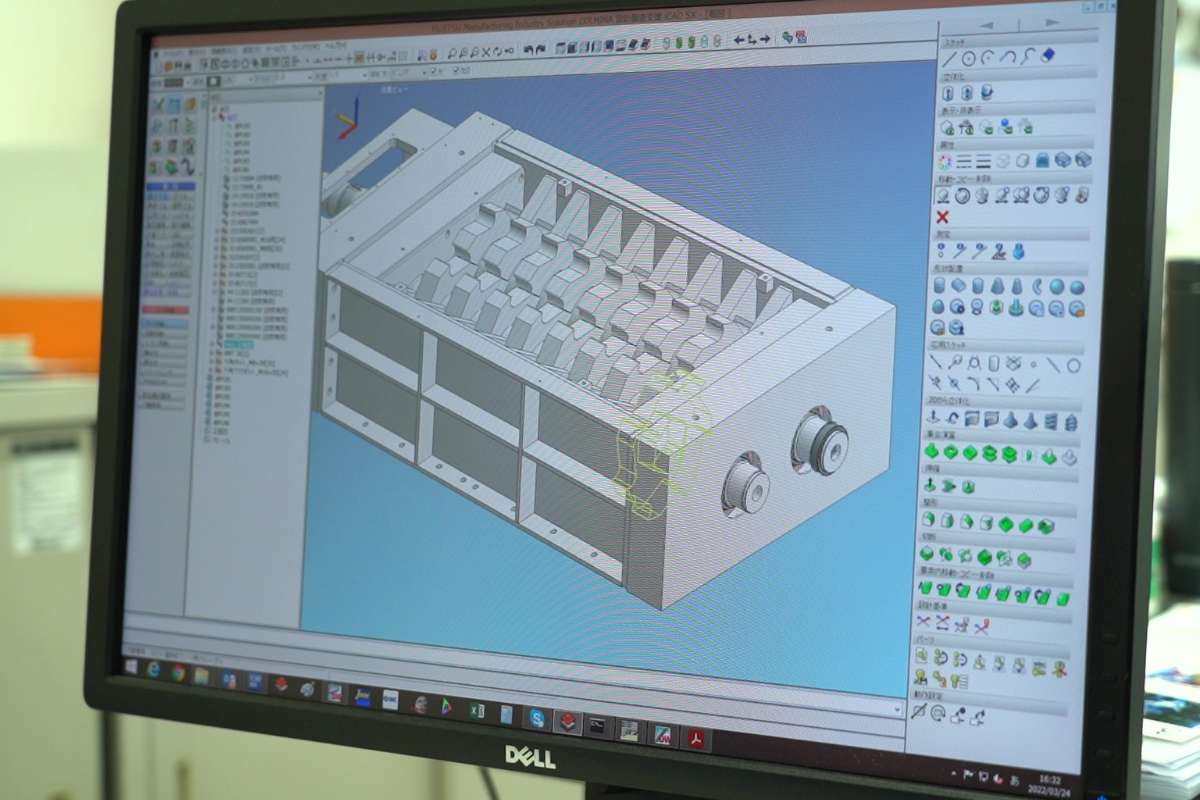

Drawing (design and production)

Material Analysis

Padding Repair

Heat treatment facilities

Metal heat treatment equipment

Vacuum quenching furnace (2 units)

900W x 900H x 1200L 1500kg/ch

Tempering furnace (6 units)

900W x 900H x 1200L 1500kg/ch (3 units), etc.

Related facilities

automatic guided vehicle transport system

The quenched products can be automatically transferred to the cooling room, which reduces the load on workers and ensures safety, thereby improving productivity.

cooling device

Heat treatment is stable throughout the year, unaffected by temperature differences.

Development of improved steel products

Comparison of crushed materials

Blades made of common steel

Cutlery using improved steel grades

Comparison of blade life

General steel material that has been in use for approximately one year

AEN in use for approximately one year

Business Strengths

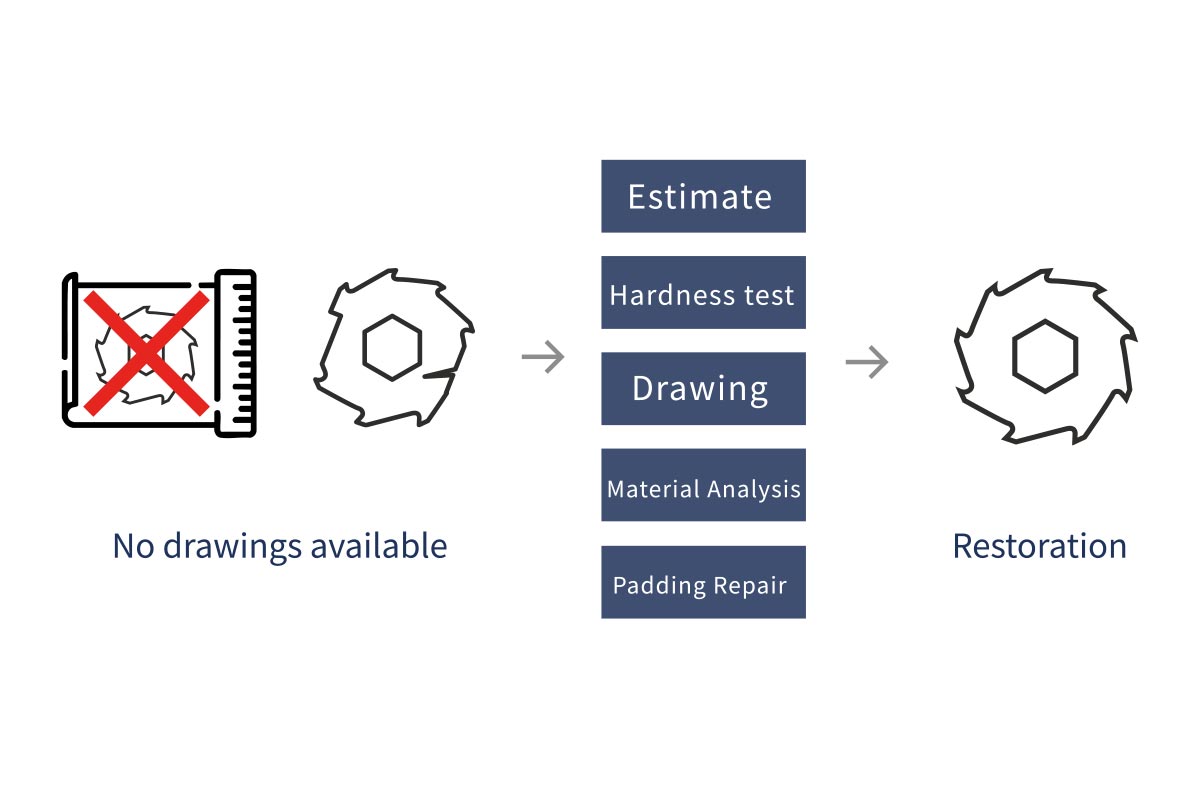

Cutlery restoration technology

Please contact us even for crushers without drawings. We can maintain crushers of all makes.

Crusher Maintenance

Our strength in blade manufacturing enables us to provide high quality manufacturing through maintenance.

Environmental Equipment Business Delivery Record

To Our Corporate Customers

Catalogs containing detailed information on our technologies

and products can be viewed and downloaded below.